Products

-

48 Channel 5V 60A 120A 300A battery cell capacity grading machine for prismatic cell

The device can provide output functions such as constant current mode, constant voltage mode, constant flow constant voltage mode, constant power mode, constant resistance mode, and DC internal resistance mode (DCIR) according to user requirements. Through the step editor, multiple working modes can be edited for mixed operation, and can be quickly switched. When the same device operates in multiple channels, the channels are completely independent of each other.

-

Automatic Laser Production Line Scheme For Pouch Battery

The production line is mainly used in the back part application process of polymer flexible packaging battery, the whole line is composed of industrial robot feeding, ear cutting and sorting, artificial assembly, ear bending, AI intelligent appearance detection, continuous laser welding, automatic blanking and so on. -

Full Automatic Laser Production Line Of Prismatic Battery

The production line is mainly used for the application process of the back part of the Prismatic battery, the whole line is carried by the robot, OCV sorting,scanning code in groups, plasma cleaning, automatic coating, automatic stacking of the robot, and the robot handling module, aI polarity testing and pole addressing, pole laser cleaning, bus bar laser welding, AI welding scar detection, insulation withstand voltage test, battery package comprehen sive performance testing equipment in each section. The production line adopts Modular design and assembly, flexible and optional combination, easy to install and debug, and easy to upgrade the production line in the later stage. -

Semi-Automatic Production Line (Laser Welding) For Prismatic Battery

The production line is mainly used in the application process of the rear part of the Prismatic aluminum shell battery, for cell sorting, AI intelligent polarity detection, automatic cleaning, automatic laser, AI intelligent welding scar detection, insulation withstand voltage test, voltage difference, resistance difference test, artificial assembly and comprehensive detection. The front line body completes the module PACK welding and the previous process making through the module integration and the double-speed chain, and realizes the automatic moving load and the back line body realizes the linkage through the linkage type moving load, the back part of the line body is mainly operated by manual double speed chain. -

Small Cylindrical Battery Universal Automatic Production Line Program

This production line is mainly used for 18650/21700/26700/32700 and other cylindrical cell PACK process. Production Process: first through theintegration of belt feeding, surface pad and then scan code and check the internal resistance, voltage and other parameters of the test sorting,lengthening the channel storage cell, the second scan code binding composition of relevant project data, each battery pack achieves dataprecision query traceability. Then it is put into the bracket by man or robot to carry out AI intelligent appearance detection, and then it flows into thenickel plate loading station, and then carries on double-sided automatic spot welding, and finally disassembles the welding fixture by the manualoperating table. -

Lithium battery welder 20000RG

The correct use method of battery automatic spot welding machine is as follows:

During welding, the position of the pole of the battery automatic spot welding machine should be adjusted first, so that when the electrode is just pressed onto the weldment, the electrode arms remain parallel to each other.

-

Lithium battery welder 20000RF

Applicable to electric vehicle battery pack, street lamp battery pack, automobile battery module, balance vehicle battery pack, scooter battery pack, mobile power supply, starting battery pack module, power tool battery pack, notebook battery pack, various electronic products and other battery combinations!

-

Lithium battery assembly automation production line (manned)

For how to automate the new energy vehicle motor production line, we can realize it from the following aspects.

Layout of new energy vehicle motor production line: In the assembly production line, the equipment type is configured according to the process flow, and the equipment is reasonably configured according to the requirements of the production rhythm. The operation direction should be unified, and the equipment spacing should be as small as possible.

-

Lithium battery assembly automation production line

The assembly line has realized the automation of the whole process of battery and module loading, sorting, assembly, welding, testing and other links, with a stable rhythm. At this stage, the automatic detection system, automatic calibration and automatic processing system are added in the key steps of production, which completely uses the manipulator to replace the traditional manual complicated operation and ensure the stability of product quality. At present, the actual operation data show that the overall operation of the production line is safe and stable, the processing efficiency is high, and the quality of products is stable.

-

Vision CCD testing equipment

As the name suggests, visual inspection and inspection belong to inspection products. Any product from all walks of life can be inspected using CCD visual inspection inspection. In the industry, inspection occupies an important part, and manual inspection of products is no longer required. This not only reduces labor costs, but also be more efficient for delivery time.

-

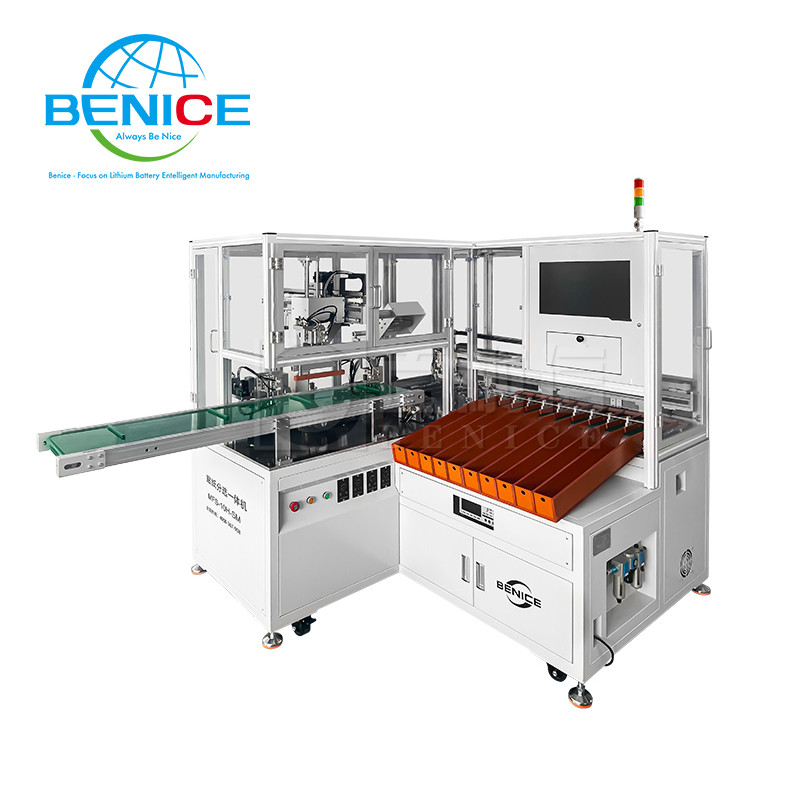

Sorter MFS-10H-SM

Separation process of lithium battery sorting machine:

Turn on the main power supply and switch on the load.

Turn on the key switch on the main control equipment.

Press and hold the switch on the main control equipment to change the working state of the battery sorter from pause to work.

Turn on the computer and run the simulation test program.

-

Sorter MFS-10G-SM

The lithium battery sorter adopts a new hopper type automatic feeding structure, which is high-speed and stable, has no impact and scratch on the battery, and is suitable for direct manual whole box feeding of different material boxes, and can complete uninterrupted production.

The 18650 lithium battery sorter adopts a high-precision and high-stability internal resistance detector for the detection part and a high-speed and high-stability feeding mechanism for the feeding part.